Heater Exchange IPCO plug

IPCO Plugs (IPX1 and IPX4) can seal tubes in heat exchangers more safely and faster (preventive) than traditional systems. This saves you a lot of time and money. In short: Maintenance without delay!

The design, production and installation of the IPCO Plug meets the essential and strict safety requirements of the Pressure Equipment Directive (PED). This is verified and validated by DNV as Notified Body through a declaration of conformity. This offers the customer additional certainty.

- Provides a safe and reliable seal

- Does not cause damage to adjacent tubes and the tube sheet, thanks to the controlled installation force

- Is reliable during the life of the heat exchanger under the most severe conditions

- Has a correct, simple and clear check of the sizing of the tube, thanks to the supplied size caliber

- Has lower installation costs compared to welded, explosive or other mechanical plugs

- Is systematically subjected to leak, blow out, deformation and break tests

Pressure Equipment Directive (PED)

IPCO Plugs are installed in pressure equipment (heat exchangers), which involves risks. IPCO Plugs comply with the ASME PCC-2-2022 article 312 and the essential safety requirements in accordance with the PED directive. IPCO has procedures in place to ensure that design, calculations, safety regulations, material selections and production always takes place in accordance with the regulations. The PED label is required for products of high quality

IPCO Plugs are manufactured under strict supervision:

- The production line of the plugs is fully traceable and identifiable.

- All materials used have a valid material certificate.

- The plugs are exposed to various tests throughout the entire process.

- IPCO is ISO-9001 certified and thus guarantees constant quality of the IPCO Plug.

In order to ensure these statements, the IPCO Plugs have been inspected by notified body DNV according to PED modules B and D. This is documented in a declaration of conformity. These modules are linked to the ISO certification. They state all relevant matters, such as the applicability of pressure and temperature in accordance with EU standards, harmonized materials, calculations and drawings. IPCO is dedicated to put in any effort to supply safe and sustainable products. IPCO also sets high demands on suppliers, raw materials, storage, product packaging and internal and external quality controls. This to relieve the customer of any worries.

IPCO Plug X1 (IPX1) Kit

An IPX1 kit consists of 10 plugs, a brush and a size caliber

X1 Plugs are available in the following materials

- ‘A’ for 16Mo3

- ‘B’ for Brass

- ‘C’ for Carbon steel

- ‘D’ for Duplex

- ‘E’ for 304L

- ‘M’ for Monel

- ‘S’ for Stainless Steel 316L

- ‘ST’ for 321

- ‘SV’ for 904L

- ‘T’ for Titanium

OPERATING PRESSURE AND TEMPERATURE IPX1

The IPX1 can withstand extremely high working pressures and therefore works in all heat exchangers through the toughest conditions. The maximum working pressure and temperature of the IPX1 depends on the size and material of the plug. If the application puts even higher requirements for the plug than what is already possible by default, IPCO can, on request, carry out additional investigations and tests to meet your specifications.

IPCO Plug X4 (IPX4) Kit

An IPX4 kit consists of 10 plugs and a size caliber. The X4 plugs have an operating pressure up to 175 bar and a much larger diameter range than the X1. The advantage of the larger range is that less stock is needed and that ordering the correct size is easier.

X4 Plugs are available in the following materials:

- ‘A’ for 16Mo3

- ‘B’ for Brass

- ‘C’ for Carbon steel

- ‘D’ for Duplex

- ‘E’ for 304L

- ‘M’ for Monel

- ‘S’ for Stainless Steel 316L

- ‘ST’ for 321

- ‘SV’ for 904L

- ‘T’ for Titanium

OPERATING PRESSURE AND TEMPERATURE IPX4

While the working pressure of the X4 can be up to 175 bar, the temperature of the IPX4 remains dependent on the material of the plug. If the application sets even higher requirements for the plug than what is already possible by default, IPCO can carry out additional examinations and tests on request to meet your specifications.

Accessories

IPCO Plug

IPCO PLUG INSTALLATION SET

The installation set consists of a hydraulic ram, hose and an airdriven hydraulic foot pump; supplied in a robust trolley case c/w insert. The IPCO Plug ram is specially designed to install the IPCO Plug and a high level of safety was taken into account in its design. The ram is fitted standard with a robust break-out protection. In the most extreme case, this prevents the pull rod from slipping out of the ram. It is possible to remove this protection when working in confined spaces. Furthermore, the IPCO Plug ram always installs the plug in one go. This saves time, prevents human error, improves the performance of the IPCO Plug and prevents damage to the tools.

IPCO PLUG HAND INSTALLATION TOOL

In addition to the IPCO Plug installation set mentioned above, we offer also an alternative: the IPCO Plug Hand Installation Tool, HIT. The HIT can be used when only a few IPCO Plug products have to be installed, and/or there is a hard-to-reach location and/or no air connection is available. The HIT can be used manually or with a battery powered impact drill. These possibilities can be determined according to environmental requirements and user preferences.

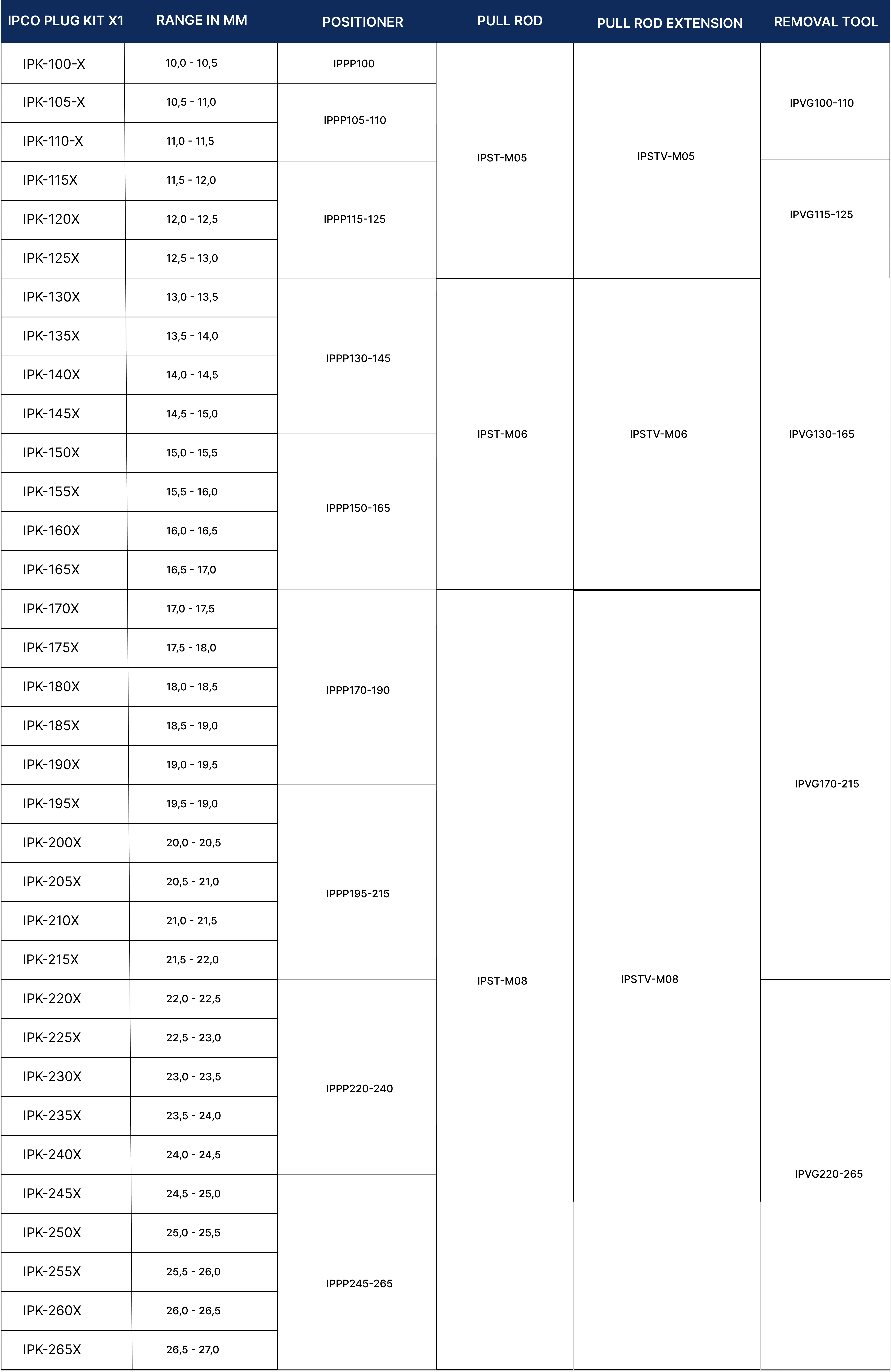

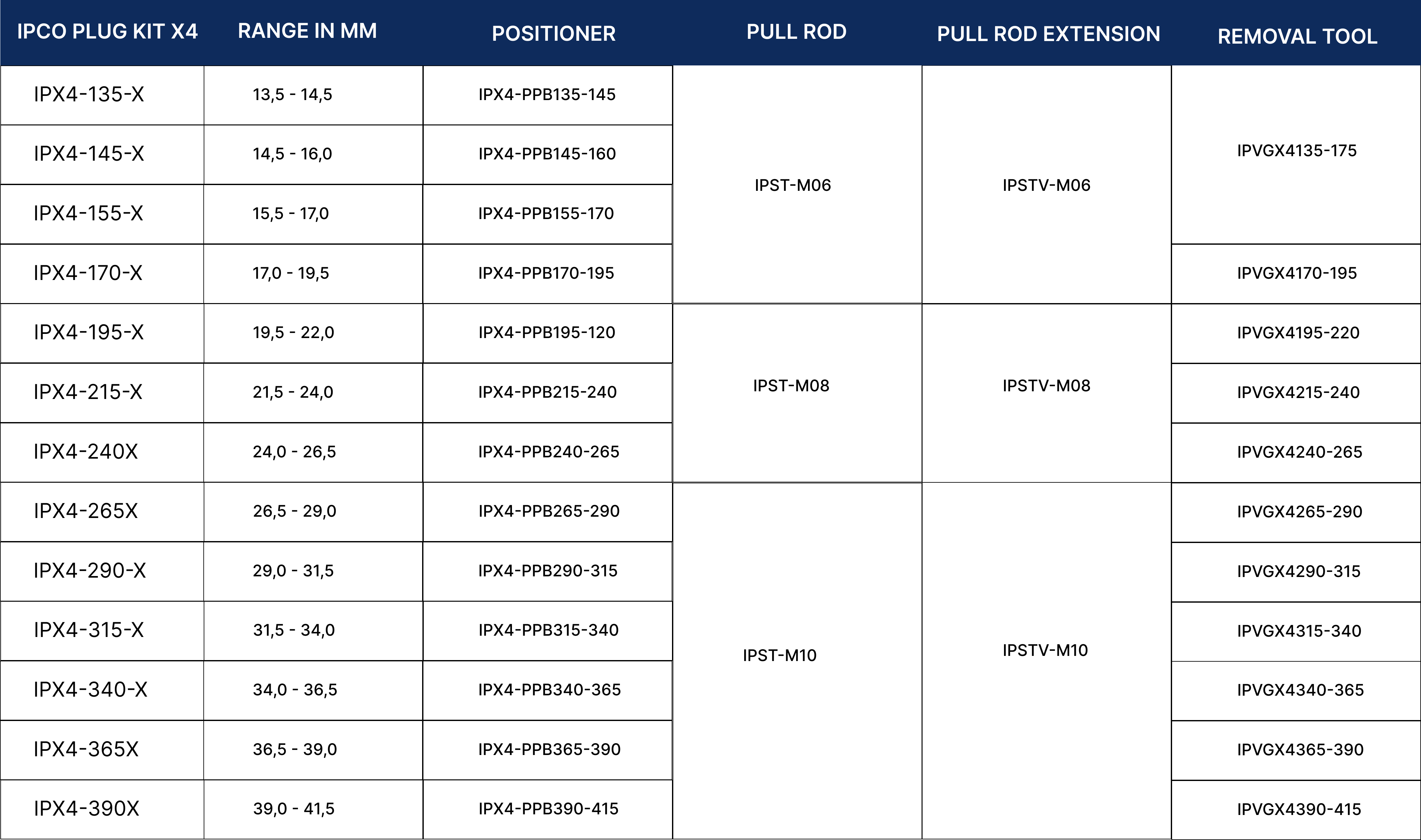

PULL ROD AND PLUG POSITIONER

In order to install the IPCO Plug, it is necessary to use the correct pull rod. Both types IPCO Plug X1 and X4 use the same four pull rods. For each size group, this consists of a pull rod, knurled nut and a spacer ring. The X1 and X4 do each have their own series of plug positioners, which are listed in the tables on pages 9 and 11.

PULL ROD EXTENSION

To install a plug, a complete IPCO Plug pull rod is required. If necessary, a pull rod extension may be needed. The pull rod extension is used if water boxes, channel heads and/ or baffles are present or with Air Fin Coolers. The extension is connected to the (standard) complete IPCO Plug pull rod. The IPCO Plug pull rod extension is available as standard in lengths of 300mm. This allows the user to extend the complete IPCO Plug pull rod in steps to reach the desired length.

CALIBER SET

To check the correct plug size, a size caliber is used. Each IPCO Plug kit contains a size caliber. With a complete caliber set (supplied in a case), you have all the IPX1-plug sizes at your fingertips. With this caliber set, you can also determine before installation which brush is needed to insert the IPX4-plug. This prevents unnecessary stock or having to return products afterwards. The engraved size number of the caliber corresponds with the size of the IPX1-plug or IPX4 brush.

BRUSH SET

Before securely sealig the tube or tube sheet, the inside must be brushed. The IPCO Plug brush has been developed for 3 applications:

- Cleaning, removal of deposits, pitting and oxidation / corrosion

- Re-rounding the tube or tube sheet hole

- Roughening the material surface so that the plug gets a good grip.

Two types of brushes are available: a brush for hard materials and one for soft materials. The brushes are available in three different ways: separately, as a set to match the IPX4 or a case with all IPCO’s brushes. The last options means that you always have the right brush size on-hand.

IPCO PLUG REMOVAL TOOL

In rare cases, it may be necessary to remove plugs. For example, if the pipe is insufficiently pre-processed or is cracked/ torn during excessive (post-) rolling. With the IPCO Plug removal tool, plugs can be removed evenly, quickly and easily. This manual tool consists of one piece. This makes it simple, robust and durable.